I sharpen my tungsten on a bench grinder, which works well as long as the tungsten is long/semi long although once the tungsten gets short sharpening becomes difficult. The tungsten gets hot quick and is hard to hold. So I began to search around for holders, I know some people chuck the tungsten up in a drill and go to town. If that works for you great, for me I like to spin the tungsten with one hand and hold it steady in the other to get a nice taper.

So one day I was browsing some magazines at work and came across these pin vises which are used to hold small brush shafts and a light bulb went off. Ordered one of each type available to give them a try and here is the results. The vises are adjustable from almost nothing up to an 1/8", so naturally it should work on 1/16", 3/32", and 1/8" size tungsten.

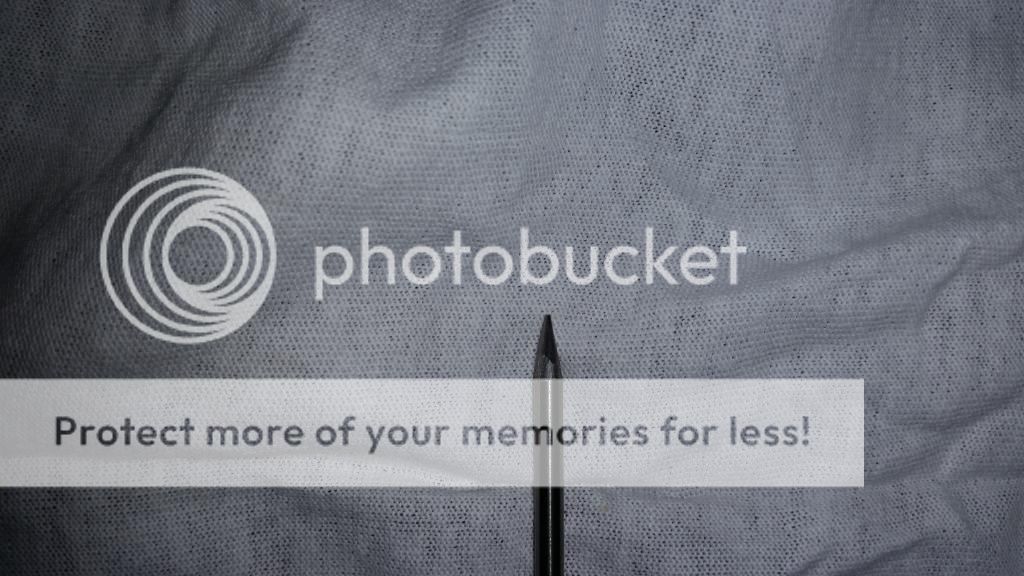

1/8" Tungsten

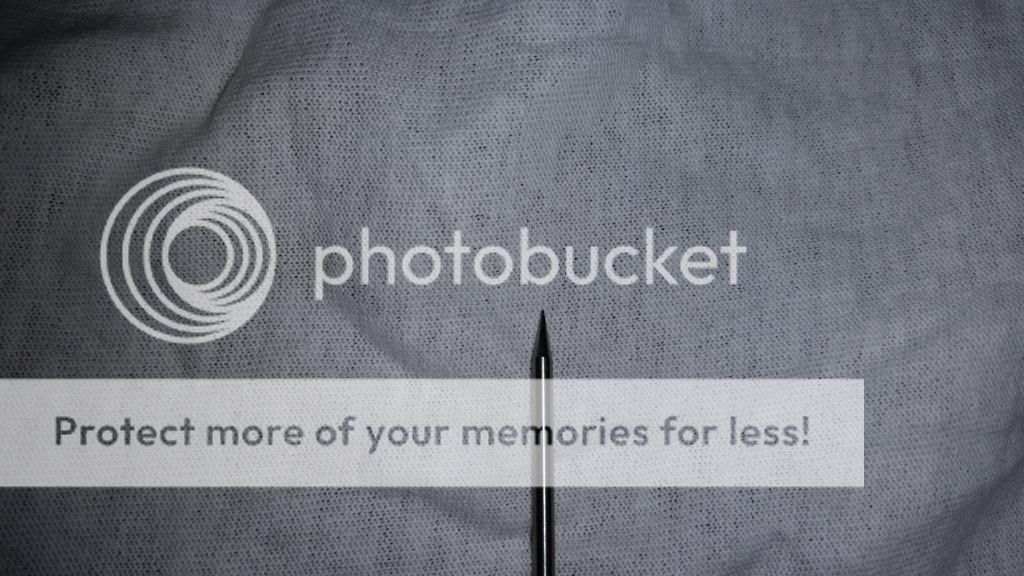

3/32"

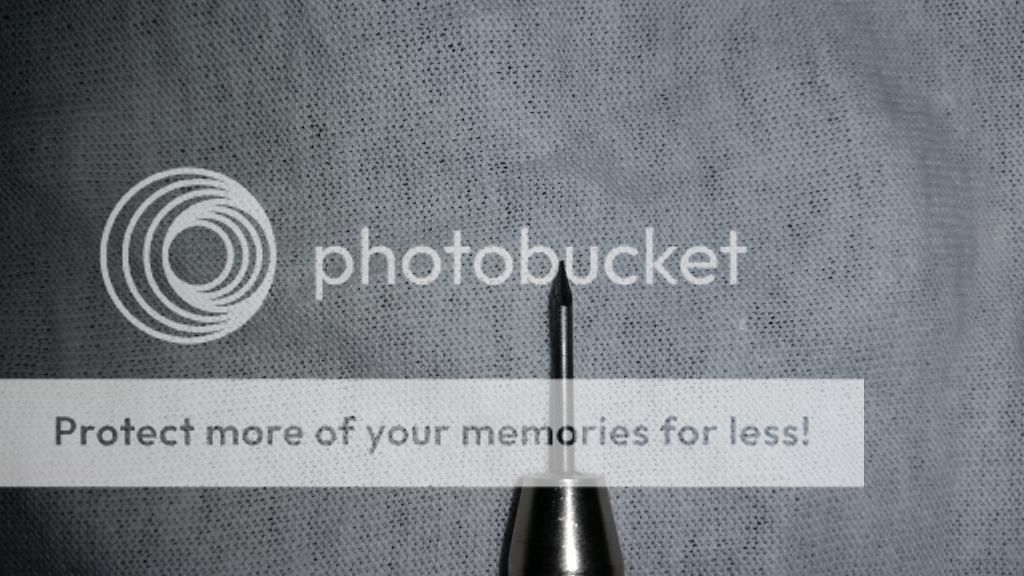

1/16"

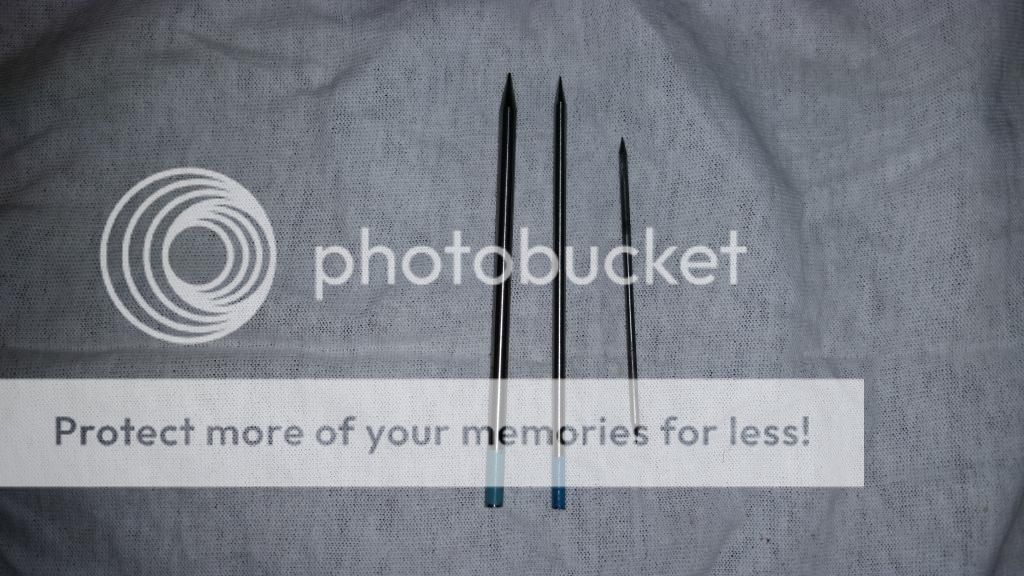

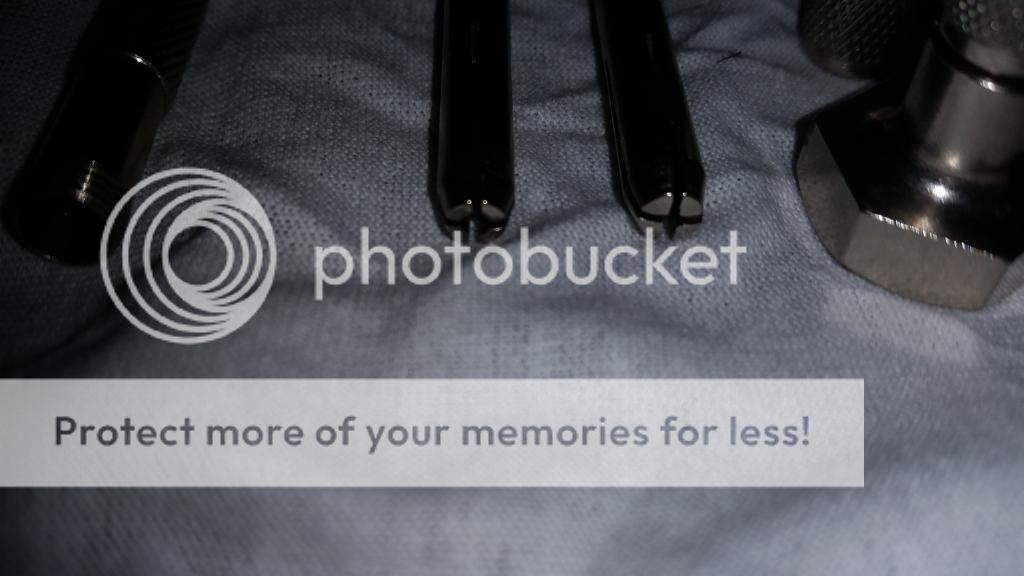

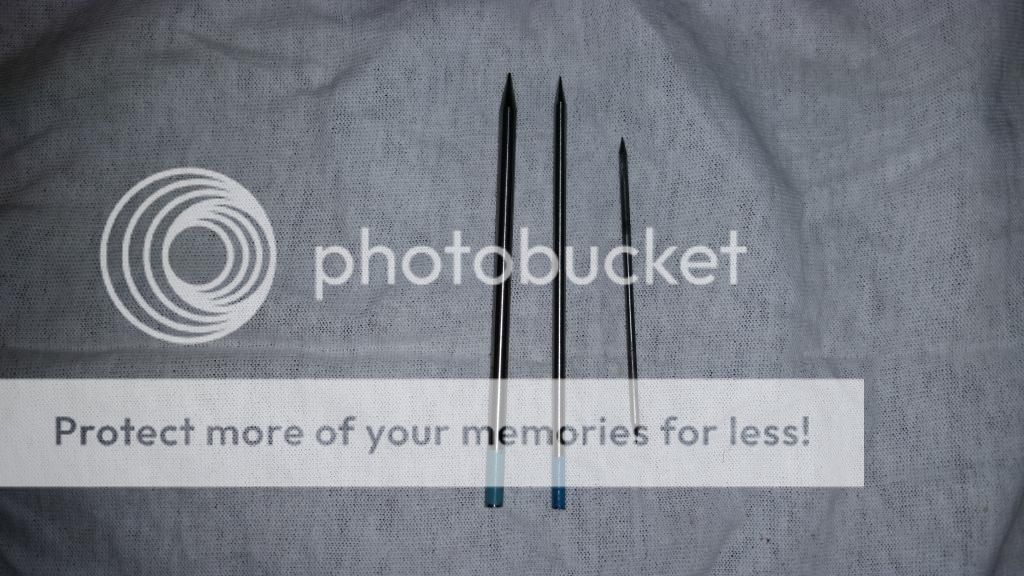

All three sizes side by side

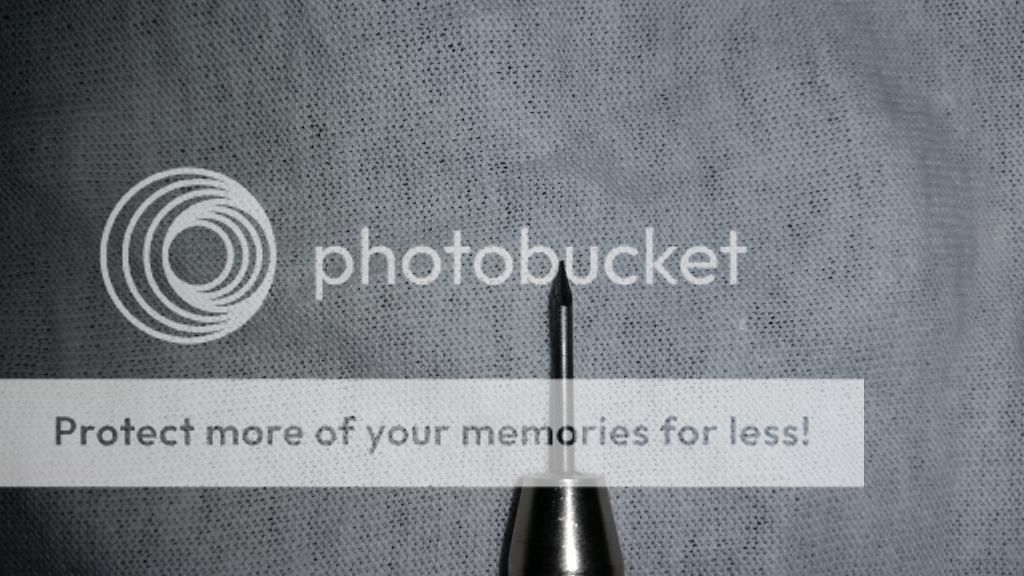

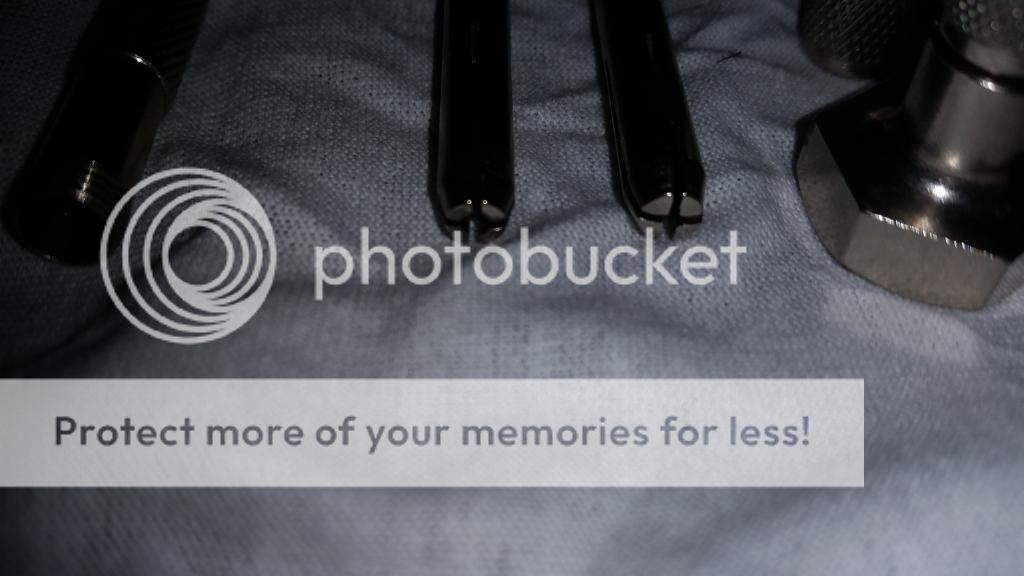

Parts of the vise

Only one slight modification need to be made, spread the slats a little bit to better accommodate the tungsten

Part numbers and the two vises side by side

Conclusion; these vise work great, they hold the tungsten tight with no movement at all. I ordered these from a local hydraulic repair shop, both vises cost $21.00 shipped to his shop. They can be purchased online although it seems there back ordered of some sort. If you are interested in purchasing any one of these. Do a google search or go to a local hydraulic repair shop.

So one day I was browsing some magazines at work and came across these pin vises which are used to hold small brush shafts and a light bulb went off. Ordered one of each type available to give them a try and here is the results. The vises are adjustable from almost nothing up to an 1/8", so naturally it should work on 1/16", 3/32", and 1/8" size tungsten.

1/8" Tungsten

3/32"

1/16"

All three sizes side by side

Parts of the vise

Only one slight modification need to be made, spread the slats a little bit to better accommodate the tungsten

Part numbers and the two vises side by side

Conclusion; these vise work great, they hold the tungsten tight with no movement at all. I ordered these from a local hydraulic repair shop, both vises cost $21.00 shipped to his shop. They can be purchased online although it seems there back ordered of some sort. If you are interested in purchasing any one of these. Do a google search or go to a local hydraulic repair shop.